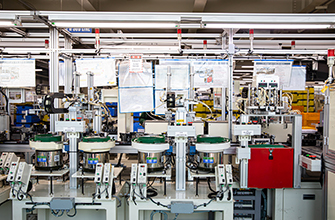

Assembly Facilities

Assembly operations

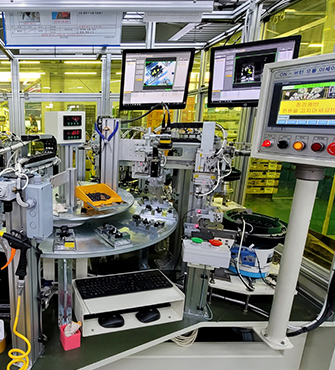

SJ AUTOTECH Co., Ltd. has various assembly facilities from LATCH ASSEMBLY LINE to SINGLE ASSEMBLY MACHINE, and has been responding appropriately to customer needs.

Lines that require multiple assembly processes, such as LATCH SUB products, are operated with optimal flow operation through LOB (Line Of Balance) analysis, and in the case of single-action assembly, the line is operated with the optimal working method through motion analysis.

LATCH ASSEMBLY LINE

TAIL GATE ASSEMBLY LINE

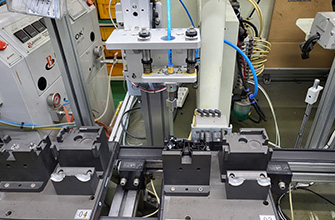

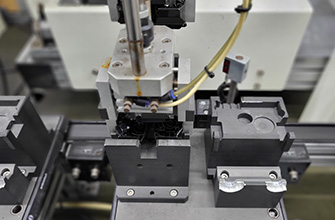

SINGLE ASSEMBLY MACHINE

-

CARRIER PLATE ASSEMBLY MACHINE -

AT SHIFT LEVER ASSEMBLY MACHINE -

CPD ASSEMBLY MACHINE -

KNOB BUTTON MODULE ASSY ASSEMBLY MACHINE